DEVENS, Mass. – The giant machines churning out metal parts on this factory floor do not bang or clang – or make any other noise usually associated with heavy-duty manufacturing.

They hum.

“It sounds like a data center in here,” said John Hart, a co-founder of VulcanForms, a start-up 3D printing company that grew out of his research at the nearby Massachusetts Institute of Technology and offers a glimpse of how the Biden administration would like to reshape the U.S. industrial economy.

VulcanForms, which recently raised $355 million in venture funding, exemplifies the type of manufacturing – cutting edge, clean, futuristic – that needs to flourish to achieve that ambition.

A wave of government initiatives, including billions earmarked for semiconductor factories and other advanced technologies, have raised the profile of the factory sector in a way few thought possible not long ago. Some suggest the United States is poised for a manufacturing renaissance, aided by what is emerging as a de facto industrial policy, an economic development approach in broad use in many parts of the world but largely absent in the United States where free marketeers who see it as picking winners and losers have long held it at bay.

Now even many Republicans whose opposition to such “central planning” strategies was long a defining party trait have thrown their hats into that ring in the wake of Donald Trump’s ascendancy as their leader and his unapologetic “America-first” view.

Bitter partisanship has kept many of them critical of Biden’s evolving approach, but since Trump’s appearance on the scene they have embraced iterations of their own, such as backing millions in public funds for FoxConn’s faltering high-tech plant in Wisconsin.

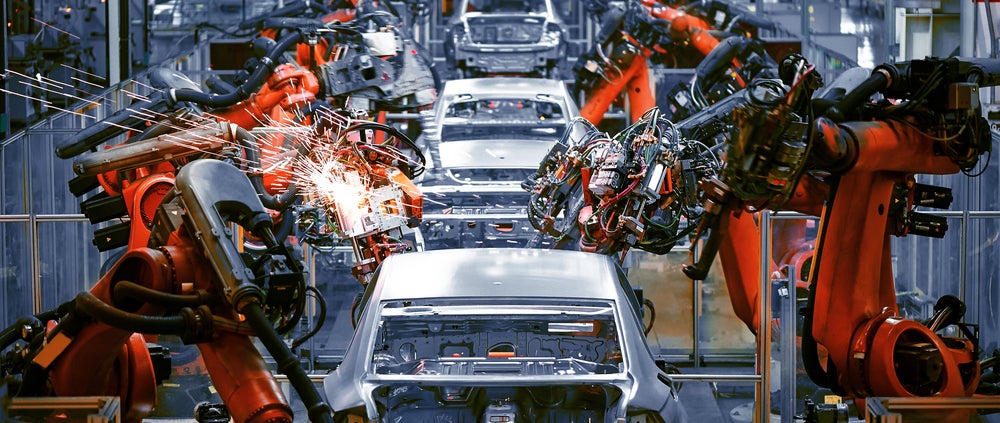

VulcanForms builds metal parts by layering on and fusing together materials bit by bit — rather than cutting them out of blocks of metal or stamping them out in metal foundries.

Hence the hushed production floor. Each of the 10 machines lined up at the VulcanForms factory funnels together 150 separate laser beams into a sealed box, where a mechanical gantry sweeps back and forth at high speed, setting down layers no thicker than a human hair as it forms parts. The factory has made everything from medical implants and gun suppressors to tire molds and computer cooling devices. VulcanForms supplies parts for a dozen defense programs, including the F3 Joint Strike Fighter jet.

Greg Reichow, a former Tesla Inc. manufacturing leader and general partner with Eclipse Ventures, the private-equity company that invested in VulcanForms, said factories like this should help avoid the supply chain shocks seen in the past two years, when many manufacturers struggled to get parts from factories overseas during the pandemic.

“You can build parts for phones one day, aerospace parts the next day,” said Reichow, “so this dramatically increases the efficiency and speed of manufacturing.”

To view the full article, please click here.